When software nerds run the factory floor

Traditional manufacturing: where good products go to be forgotten.

1. Set the scene: a tale of dusty dreams and empty wallets

Imagine you’ve just launched your dream hardware startup. You’ve spent months perfecting your PCB design, tweaking every trace, optimizing every capacitor placement. You’ve also designed a custom enclosure to fit it perfectly. You’re ready to take the world by storm, so you do what every hopeful entrepreneur does—you order 1,000 PCBs and matching enclosures upfront to get that sweet bulk discount.

Fast forward six months.

Half of those PCBs and boxes are still sitting in your office, collecting dust. The other half? Obsolete because you had to tweak the design after customers pointed out a minor, but catastrophic, flaw. Now, you're stuck with 500 tiny reminders of your past optimism, each whispering, "You should’ve waited."

When your inventory strategy is ‘buy now, hope later.’

Meanwhile, your competitor did something different. They waited. When a customer placed an order, then they ordered a PCB. JLCPCB shipped it fully assembled in days, and within two weeks, their product was in the customer’s hands.

Zero excess inventory, no sunk costs—just streamlined efficiency.

That is JITNO—Just-In-Time, No Overstock.

2. The JITNO Revolution

JITNO isn’t just about manufacturing—it’s about building and delivering complete products without waste or delay by relying on suppliers who follow the same principles. Instead of stockpiling enclosures, PCBs, or finished units, it ensures that every part comes together only when needed, keeping production fast, flexible, and efficient.

This is only possible when suppliers, logistics, and assembly work on demand—at prices that make sense, so every part arrives just in time to be built and shipped—no stockpiling, no wasted time, no excess.

Old Manufacturing Mentality: "Let’s build a ton of stuff and hope we sell it."

JITNO Mentality: "Let’s only build what we’ve already sold."

JITNO combines the speed of Just-In-Time (JIT) manufacturing with the flexibility of on-demand production, making it perfect for small and medium-sized businesses that don’t want to drown in unsold inventory.

One of the best examples? JLCPCB.

- Order PCBs fully assembled, on-demand – No need to source and solder parts yourself.

- Scale from 1 to 10,000 seamlessly – No forced minimum orders.

- Tap into a massive component warehouse – If you design using their stocked parts, your PCB is assembled and shipped fast.

This means that companies can wait for a customer to place an order, and only then:

- Order a PCB from JLCPCB (fully assembled, no fuss).

- Drop it into an enclosure (like one from Stack55, where you can design custom aluminum cases in minutes).

- Ship it to the customer—all within 15 days.

No storage costs. No dead inventory. No existential crisis over unsold stock.

So next time you're tempted to order 500 units "just in case," remember:

- Customers don’t care if you have stock sitting in a warehouse.

- Speed and flexibility beat bulk inventory.

- The future belongs to companies that move fast and carry nothing extra.

3. JITNO + Custom Manufacturing: How Software Devs Are Taking Over Hardware

We’ve been conditioned to believe that high-volume manufacturing equals efficiency, but that’s a lie. Mass production only works when you know you’ll sell everything. The rest of us need JITNO.

Custom Manufacturing Was Never Supposed to Exist

For most of history, manufacturing followed one rule:

Make a lot of the same thing, or go broke trying to make something different.

Factories were optimized for large production. If you weren’t making thousands of units, you were losing money. Small batch custom products? A logistical nightmare.

The why the idea of custom manufacturing on demand was considered very hard for so long. The economics just didn’t work. Until now.

Why It’s Happening Now

JITNO already revolutionized manufacturing by eliminating overstock. But combined with software-driven customization, it unlocks something bigger.

A small company can now:

- Let customers design their own products in real-time

- Use software to generate manufacturable designs instantly

- Send those designs straight to an on-demand manufacturer

This was science fiction a decade ago. Today, it’s just a web app.

Three things made this possible:

- On-demand manufacturing is real – Companies like JLCPCB, 3D printing hubs, and CNC shops offer batch sizes as small as one unit at reasonable prices.

- Software automates customization – Instead of engineers tweaking designs manually, parametric modeling allows instant adjustments based on customer input.

- Manufacturing has an API – Supply chains are connected. Software can check pricing, stock, and lead times instantly, then route production accordingly.

4. The rise of the software-driven manufacturer

This is why the biggest winners in custom manufacturing won’t be traditional factories. They’ll be small teams of software engineers who build the right tools.

- Instead of owning machines, they’ll build web-based design interfaces.

- Instead of managing warehouses, they’ll connect to just-in-time supply chains.

- Instead of predicting demand, they’ll let customers generate it in real time.

This flips the old model on its head. Cookie-cutter manufacturing tried to predict what people wanted and make it in bulk. JITNO-powered custom manufacturing waits for the customer to decide and customize, then makes exactly what’s needed, nothing more.

What this means for small companies

Launching a hardware business meant gambling on inventory. Today, with the right software, even a small company can:

- Offer customizable designs that were once only available at premium prices

- Show instant, accurate pricing

- Sell before they build

- Produce without waste

- Scale without deep pockets

Small teams, even solo founders, can now build custom hardware without factories or large funding rounds. Software isn’t just eating the world—it’s eating manufacturing, too.

So we can make custom manufacturing possible.

5. Factory finances up side down

For small companies, startups, or even solo founders, JITNO + custom manufacturing isn’t just an operational shift—it’s a financial revolution.

For decades, starting a hardware business required deep pockets. Before selling anything, you had to:

- Sink money into molds, tooling, and inventory

- Pay for warehouses to store unsold stock

- Wait weeks or months for payments to clear

This is why hardware was always considered harder than software. The financial risk was huge.

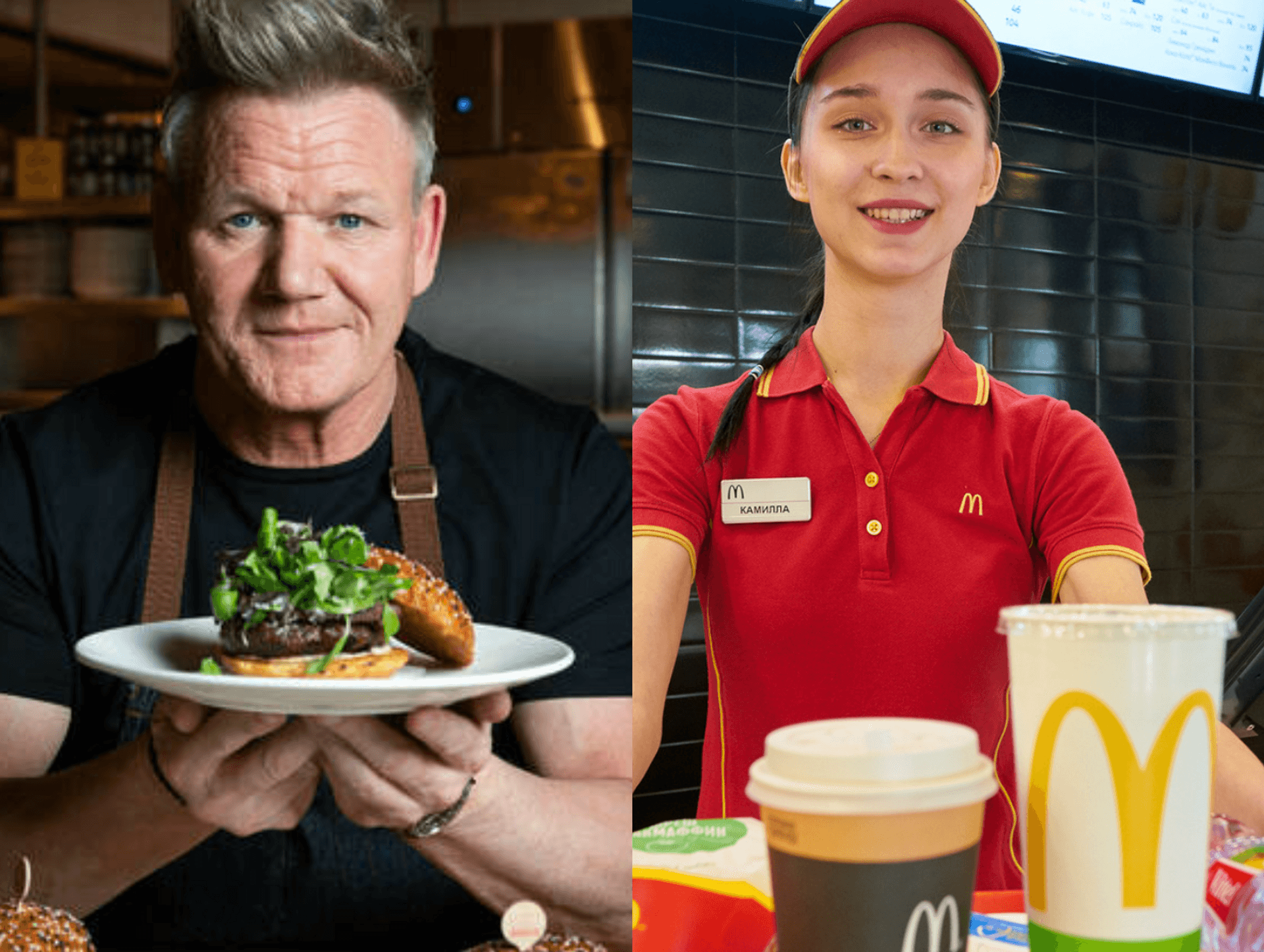

One costs $120, the other comes with fries. Choose wisely.

But with JITNO + on-demand manufacturing, that risk disappears.

Today, bootstrapping a hardware business might require just:

- A laptop – to build a website with a real-time configurator

- A Stripe account – to collect money before production even starts

- A manufacturing API – to send paid orders straight to production

No factory. No warehouse. No upfront inventory costs.

The best part? Your customers fund your company, 100%. They pay first, production happens after. Payments settle immediately, eliminating the usual 30, 60, or 90-day delays. No more burning cash while hoping sales catch up. Every order is profitable from day one.

The biggest barrier that kept small players out of hardware—the need for big capital—is now gone. Anyone with the right software can compete.

6. Small Companies, Big Winners

Mass production forces companies into a race to the bottom—lower prices, thinner margins, endless competition.

Making custom, on-demand products is a different game that plays by different rules. It was possible as an alternative, but it was slow, expensive, and difficult to scale. If you wanted to sell custom-built parts, precision-machined hardware, or small-batch electronics, you needed serious money.

JITNO + customization changes that.

Instead of betting on a mass-market product and hoping it sells, small companies can make exactly what customers want, at a price that works.

- No inventory risk – Products are made after a sale, not before.

- Higher perceived value – Custom solutions command premium pricing.

- Bigger margins – You’re not fighting on price—you’re selling uniqueness.

A small team with a smart configurator can run a lean, profitable business.

What the Future holds...

So who wins in this new world?

- Small teams of software engineers who build great design tools.

- Makers and product designers who want to sell unique, high-value goods.

- Lean businesses that don’t want to deal with warehouses, bulk inventory, or supply chain headaches.

Instead of betting on a mass-market product and hoping it sells, small companies can make exactly what customers want, at a price that works.

A few years ago, this would have required a factory and a full production team. Now, a small group of engineers with a smart configurator can run the whole thing.

Now, go forth and manufacture only what you need, when you need it. Your wallet, sanity, and future self will thank you.

Ready to embrace JITNO? Try designing a custom enclosure on Stack55. No commitment, no overstock, just pure efficiency.

Published